Our Water Stewardship Approach

At ACS Clothing Ltd., we recognise water as a shared resource that underpins healthy communities, resilient ecosystems, and quality garment-care services. Our commitment is to use water responsibly, transparently, and in collaboration with stakeholders.

What we do today

- Source & context: We map our operational water use across processes (e.g., garment care, facility services) and maintain metering to track consumption trends and process efficiency.

- Risk & governance: We assess water-related risks in our operating regions, consider community and environmental needs, and review these risks annually through our ESG governance process.

- Efficiency & targets: We manage water intensity in our operations and are formalising measurable, time-bound reduction targets with annual progress reporting.

- Innovation & reuse: We are exploring and piloting measures to reduce, reuse, and recycle process water where feasible, while maintaining product quality and hygiene standards.

- Benchmarking: We compare our approach with sector guidance and peer practices so we continually improve against industry expectations.

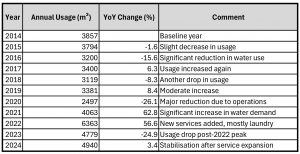

In the past 12 months, ACS Clothing Ltd. used a total of 4,940 cubic metres of water — equivalent to 4,940,000 million litres. This figure reflects the scale of our operations as a large-volume garment processing facility and includes water used across cleaning, sanitisation, laundry, and other core textile care services.

Given the water-intensive nature of our industry, we continue to prioritise water efficiency and conservation. We are actively investing in closed-loop systems, rainwater harvesting, and recycling technology to reduce overall consumption and minimise reliance on potable water sources. We also track and benchmark water usage per garment to drive further reductions over time.

This volume will serve as a key performance baseline as we continue our efforts to improve operational sustainability and support SDG 6 (Clean Water and Sanitation) and SDG 12 (Responsible Consumption and Production).

Water Conservation Practices

34 Water Management Policy_rev2

Water conservation in our offices & plant (majority of sites):

Installed low-flow faucets, taps, toilets, urinals, and showerheads across most facilities.

- Harvest rainwater for non-potable applications (e.g., washdown, irrigation).

Recycle laundry process water — the final two rinse cycles are captured, filtered, and reused.

Recirculate/reuse coolant water in applicable processes.

Educate staff on water conservation through training, signage, and SOPs.

ACS demonstrates a robust and holistic approach to water conservation, underpinned by its formal Water Management Policy (HR34), issued in September 2023. This policy outlines our strategic commitment to sustainable water use, applying to all employees and stakeholders, and reflects a systematic effort to reduce our water footprint across operations.

At our primary facility, which accounts for the majority of our operations, we have implemented a comprehensive suite of water-saving measures. These include:

Installation of low-flow taps, toilets, and showerheads that meet EPA WaterSense standards.

Rainwater harvesting systems for non-potable uses.

A closed-loop system that recycles greywater from our laundry processes—specifically reusing water from the final rinse cycles.

Integration of reclaimed coolant water from dry cleaning operations into our laundry process.

These initiatives are complemented by staff training, supplier engagement, regular audits, and transparent reporting, all coordinated by a cross-functional water management team. These actions are aligned with SDG targets 6.4, 9.4, 12.2, and 15.1 and directly support our ongoing emissions reduction and resource efficiency objectives. The attached Water Management Policy serves as documented evidence of our structured and strategic approach.